With “all-inclusive”, we pledge our commitment to you

Research

Innovative processes

Always with a finger on the pulse: We engage in active research and development in order to provide our customers with innovative processes. In doing so, cost efficiency and process reliability remain at the center of our efforts. Our inventiveness has received several accolades with the GKV Technical Parts Prize.

Highly transparent glass and flexible, malleable plastic. KH positions freely floating glass plates fully automatically into the tool and encapsulates them on the narrow side. The result is a type of lense with “window frames”. With the newly developed technology, previously unrealizable applications are now made possible.

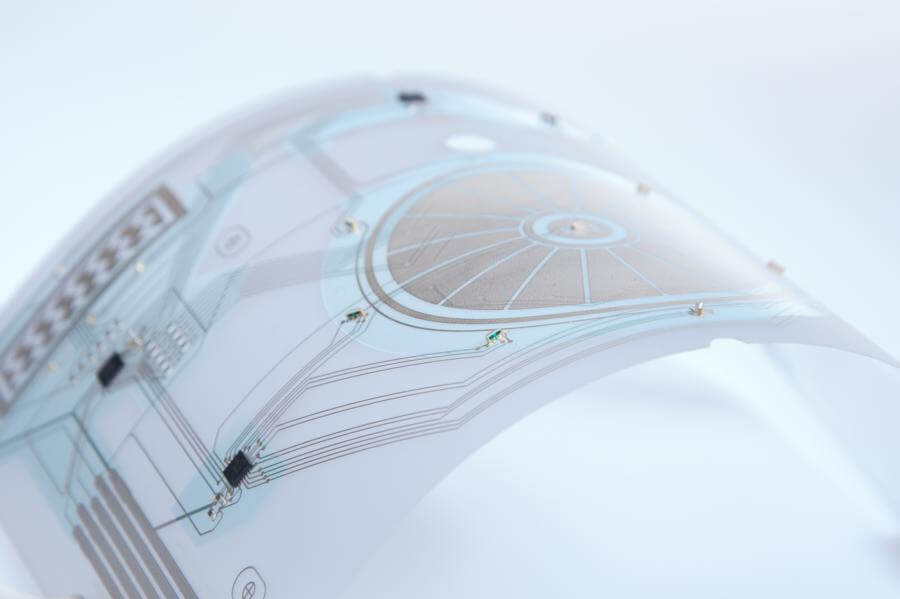

In order that capacitive control – that is, control through touching of the surface – functions, it is necessary that conductor paths are integrated into the component. We are proficient in the entire process, including the printing of the foil and the fitting of electronic components.

Before back molding:

Printed conductor paths

with electronic components

Conventional keys on electronic devices require gaps in which dirt, and therefore germs, are able to collect. For this reason, a product with a sealed surface is ideal for the Medtech sector. This is made possible with capacitive control concepts and In-mold labelling.

Sealed surface with scratch-resistant coating and vanishing effect:

Symbols appear through backlighting

Why KH Medical?

Everything from One Source

To benefit the most from our know-how, it’s best to come on board at an early stage. In this way, the first idea can already be optimized specifically for plastics and production, ensuring that the later realization runs successfully and efficiently. Depending on the number of pieces, various production concepts can be developed which are all naturally aligned with FDA and MDR.

Applications

Together with you, KH Medical sets new standards in the healthcare industry.